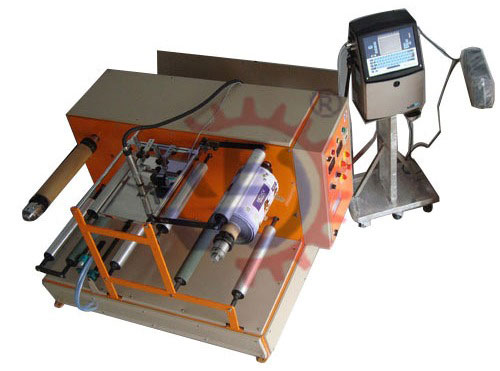

Doctoring Rewinding Machine

We have been successfully manufacturing, exporting & supplying all types of Doctoring Rewinding Machine and Winding Rewinding Machine for Inkjet and Batch Printing since last 25 years from Ahmedabad, Gujarat, India. We are winner of 3 times National Award and 2 times International Award for Quality manufacturing.

KEW Manufacturers, exports & supplies Doctoring Rewinding Machine with high production output & efficient edge guiding function with more than 4000 installation in place all over India and overseas like Saudi Arabia, UAE, Dubai, Sharjah, South Africa, Nigeria, Ghana, Congo, Kenya, Zambia, Sri Lanka, Bangladesh, Malaysia, Pakistan, Nepal, Russia, Thailand, Indonesia, Brazil, Colombia, Venezuela, Argentina, Mexico, Canada, etc. making us the biggest manufacturer, exporter & supplier of Doctoring Rewinding Machine. Doctoring Rewinding Machine can also be used as Winder Rewinder for Inkjet or Batch Coding application.

Our Doctoring Rewinding Machine is used for all types of Laminates like, Foil, Paper, LDPE, HDPE, PVC, etc. Our Doctoring Rewinding Machine is manufactured with us most precision which ensure zero maintenance up to 10 years.

Our Winder Rewinder Machines for Inkjet Printing & Batch Printing are widely used by all Printer Manufacturers all over the world. Our Winding Rewinding Machines give efficient prompt printing an all types of laminates like, Foil, Paper, LDPE, HDPE, PVC, etc. The Batch Coding application for Winder Rewinder Machine is coupled beautifully & synchronized well.

Doctoring Rewinding Machine is used for Converting & Batch Printing Application:

Salvage Rewinding (Correcting badly Wounded Reels for Inspection & Doctoring Operation.) Printing of Mfg. Date, Expiry Date, Batch No., Sr. No,

INTRODUCTION:

In any paper, film and foil conversing industries, the Winder/Rewinder (Doctor Machine) is used widely for on-line printing of Mfg. Dt., Exp. Dt. B. No. etc. using Ink- jet printer or other contact coding machines from Roll to Roll at high speeds & then these printed roll are used in various packaging machines.

Range of Doctoring Rewinding Machine:

- 18 Different Models available.

FEATURES:

- Cantilever design balancing body for easy loading and unloading of parent / rewound reel. Movable unwind stage for Edge guiding System (Hydraulic Web Aligner).

- Mechanical 1.5 / 2.5 Kg. Optional Magnetic powder brake with tension controller & Torque control potentiometer. Provision for incorporating Ink Jet Printing System with Hot air ink drying.

- The Model is specially designed for correcting badly wounded reels for inspection & doctoring operation.

- It is great substitute to online coding / batching operation

STRUCTURE FITTING:

M.S. CHANNEL FRAME BODY with mechanical clutch & break unwind / unwind system, unwind / rewind shaft & cones for printed material holding cores for printed material cores, alum – guide roller & all other standard accessories.

ACCESSORIES FOR INKJET CODER MOUNTING INCLUDED IN THE MACHINE

Technical Specification:

- Web Width : 100 mm to 1500 mm

- Maximum Weight of Unwind: 100 Kg to 1000 Kg (Different Models for different Weight)

- Max Parent Reel dia.: 400 mm.

- Max. Rewind reel dia.: 400 mm

- Rewind Core Dia.: 76 mm

- Motor: 2 HP DC motor / 2 HP AC motor (3 HP, 5 HP also available on suitable Model)

- Max. Designed Speed: 100 to 150 Mtrs / min

SUITABLE FOR ALL TYPES OF INKJET CODER / THERMAL PRINTER:

ANY MAKE INKJET PRINTER / THERMAL PRINTER CAN BE SUPPLIED ALONG WITH OUR WINDER REWINDER MACHINE like Markem-Imaje, Domino, Videojet, Alphajet, Control Print, Jet Inks, Linx, etc.

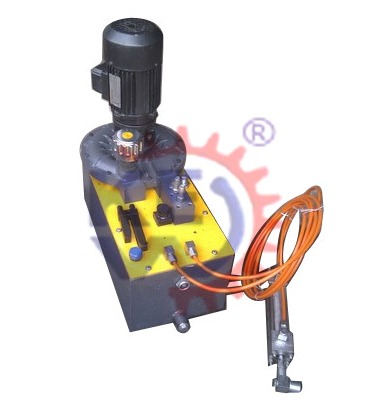

Optional Parts for Doctoring Rewinding Machine:- Line Guide System for Electronic Edge Sensing for Perfect Winding

- Air Shaft at Unwinder & Rewinder

- Tension Control System for Auto Tension at Unwinder.

- Reverse Forward System

- Stroboscopic Equipment for Inspection

- Techno Feed System to keep speed constant from start to end of roll

- Encoder for Inkjet Printer

- High Capacity Blower Fan with Heater (800W) attached to facilitate quick drying of Ink

- Slitting Arrangement

Advantages of Doctoring Rewinding Machine:

- Corrosion resistant

- Affordable

- Easy to operate

Features of Doctoring Rewinding Machine:

- Convenient height for operation

- Compact Design

- Variable speed drive

- Double drive

Various Application of Doctoring Rewinding Machine:

- Doctoring/Inspection Rewinder Machine

- Rewinding Machine for inkjet coding

- Coil Rewinding Machine

- Salvage Rewinder with Reversible Operation

我们的产品

- 报刊插图栏打印机

- 分片机器

- Flexo 打印机

- 涂布机

- 切开器 Rewinder 机器

- 检查倒带机器

- 篡改倒带机器

- 喷墨打印机的绞的倒带机器

- 与氢结合的 Pneumo 网直线对准器系统

- 网直线对准器系统

- 网引导的系统

- 卷舒展包装机

- BOPP 磁带切割机

- 核心切割机

- 边缘引导的系统

- 跟踪路辗汇编

- 开卷机机器

- Rewinder 机器

询问

Awards

关于美国

我们的公司在软包装 & 转换领域很好被体验。 我们是制造,出口和供应报刊插图栏打印机,分片机器, Flexo 打印机,涂布机,切开器 Rewinder 机器,检查倒带机器,篡改倒带机器,络纱机喷墨打印机的,与氢结合的 Pneumo 网直线对准器系统,网直线对准器系统,网引导的系统,卷舒展包装机, BOPP 磁带切割机,核心切割机,边缘引导的系统 Rewinder 机器,跟踪路辗汇编,开卷机机器, Rewinder 机器。 这家公司提供这样一项优质机械和服务。

观看更多

与我们联系

KRISHNA ENGINEERING WORKS

Punit Nagar Crossing Road, Ghodasar,

Ahmedabad-380050, Gujarat, INDIA

+91-9327940232

电传 : +91-79-25895305

+91-79-40085305

电子邮件 : info@krishnaengineeringworks.com

krishnaengineeringworks@yahoo.com

网站 : www.krishnaengineeringworks.com